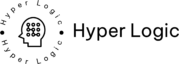

Battery manufacturing requires careful control at every production stage, from raw material processing to final assembly. The chemical processes involved in battery technology need accurate monitoring to ensure the final product works safely and reliably.

Why Precision Matters In Battery Production

Modern lithium-ion battery manufacturing involves controlled chemical processes in which even small changes can affect performance and safety. Temperature changes of just a few degrees during material preparation can change properties, affecting battery capacity and lifespan. Moisture content in electrode materials must stay within narrow limits to prevent chemical reactions that could cause thermal runaway.

The high energy density of modern batteries makes precision important. Manufacturing problems that might be minor issues in other products can become serious safety risks in batteries. Therefore, monitoring technologies are needed that can detect and prevent problems early in the process.

Critical Control Points Throughout The Energy Battery Value Chain

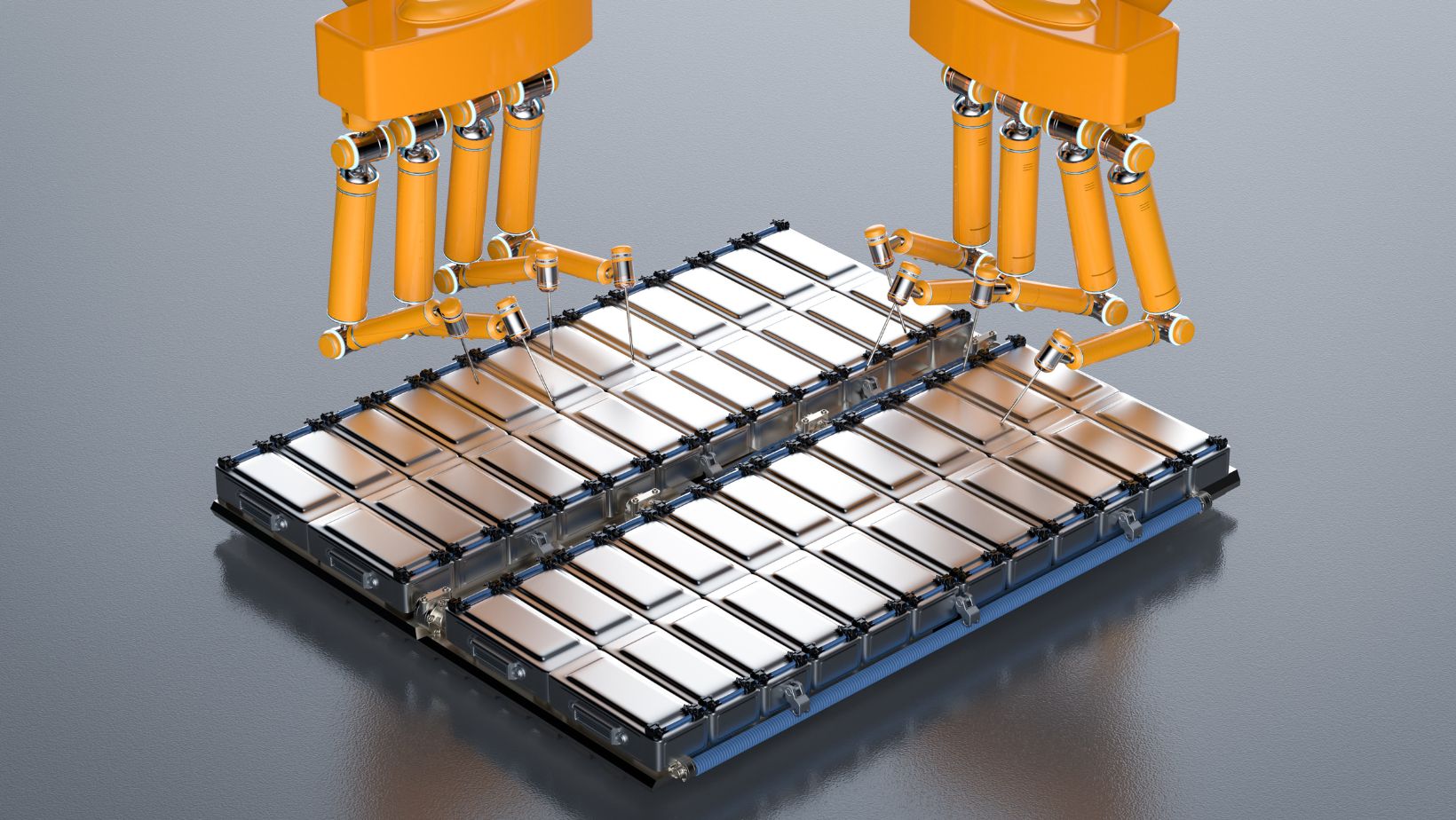

Battery production involves multiple stages where accurate monitoring is necessary. During the preparation of raw material, checking the purity of lithium compounds ensures consistent properties. The mixing and coating processes require monitoring of mixture consistency and coating thickness to maintain uniform performance.

Companies using monitoring systems throughout their energy battery value chain achieve better quality control and less waste. These approaches allow manufacturers to identify potential issues early on, preventing costly rework and ensuring consistent product quality.

Temperature And Environmental Control Systems

Battery manufacturing facilities must maintain controlled environmental conditions throughout production. Temperature changes can affect chemical reaction rates, material properties and the characteristics of the final product. Monitoring systems continuously track conditions to ensure good manufacturing environments.

Key environmental parameters requiring continuous monitoring include:

- Temperature control in mixing, coating and drying processes where changes can affect material properties

- Humidity management to prevent moisture absorption in materials like lithium salts and electrode components

- Air quality monitoring in controlled environments to prevent contamination and oxidation

- Pressure monitoring in vacuum processes used for electrolyte filling and degassing

Quality Assurance Through Advanced Monitoring

The complexity of battery chemistry requires testing procedures to verify product quality. Monitoring systems track chemical composition, physical properties and electrical characteristics throughout production. These systems help manufacturers maintain consistent quality while optimizing production efficiency.

Advanced monitoring technologies for battery quality control:

- Chemical composition analysis using methods to verify material purity and detect contaminants

- Verification of physical properties including particle size, surface area and porosity of materials

- Electrical testing of individual cells and battery packs to ensure performance requirements are met

- Thermal analysis to identify potential safety issues and optimize thermal management

Data Accuracy And Safety Implications

Monitoring precision directly affects battery safety. Inaccurate monitoring can lead to manufacturing problems that compromise safety or create conditions for thermal runaway. Good monitoring systems help manufacturers identify and eliminate potential safety risks.

Battery manufacturing is one of the most monitoring-intensive industrial processes, where accuracy directly relates to product safety and performance. As battery technology develops, high-precision monitoring is becoming increasingly important to ensuring safe and reliable production.